Dust Collection Hood Modifications (2004)

When you install a dust collection system one of the first things you realize is that the tool manufactures often do a poor job of designing the DC ports on their machines. So if you want really efficient dust pickup at the source, you’re often forced to modify the stock DC ports with more efficient home-brew hoods. Here are some of the hoods I installed on my bandsaw, router table, compound miter saw, and downdraft table. Email me if you have question about any of these.

Here is the “Hatfield Hood” I added to my Jet 14” bandsaw. It’s a 3”12”x6” register boot cut into the side of the bottom door. I ran a 6” drop dedicated to this machine, and with the addition of a brush that cleans the bottom wheel this gets the vast majority of sawdust. You can check out the page devoted to the saw (at this link) for more information.

For my router table I was able to slightly modify the stock NYW designs to improve collection. Norm designed 3” ports on the fence and in the cabinet, and I upsized these both to 4”. Since a 4” pipe pulls almost exactly ½ the suction of a 6” drop I can supply both 4” inlets adequately from a single 6” drop dedicated to this table. I also came out of the back of the cabinet with a 90 degree bend so that the piping doesn’t stick so far behind the saw. This allows me to get the table closer to the wall for storage, which frees up precious shop space. There is very little sawdust that escapes with this design. You can browse my web page dedicated to this router table (at this link) for more information. Here’s the backside of the router table to show the 4” inlets and elbow entry into the cabinet.

Here is the hood design for my compound miter saw. The box is made from scrap ½” and ¼” plywood. I sized the front opening to allow the saw to travel to the full miter positions, and be tall enough to capture the top of the blade. The edges of the box stop just at the edge of the fence. I angled the box towards the back to help with funneling the dust to a downdraft 4”x10”x6” straight register boot cut into the bottom of the table. I have a 6” drop dedicated to this saw. You can see the blastgate and vertical drop just to the left and behind the hood. At the underside of the saw I used a short section of 6” clear flex to make the 180 degree bend to the underside of the table. This works really well – better than the other designs I’ve attempted so far. Check out my page dedicated to this saw (at this link) for more information.

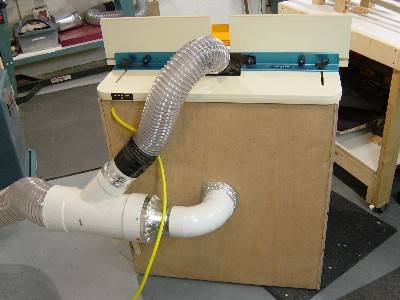

And finally, here is the hood design from my downdraft table. The box is roughly 30” square. The inlet is a 4”x10”x6” 90 degree register boot. The bottom of the table is angled to make the suction even across the entire surface. The top is gloss painted white hardboard with ¼” holes cut 1” on center from a pegboard pattern. Check out my page dedicated to this table (at this link) for more details.

© Copyright 2006 Chris Billman