Cutting Boards (2004, 2005, 2009, 2014)

After a large project I inevitably have plenty of "scrap" wood around. Like most woodworkers, I HATE to throw away any wood, so I often use it for small projects instead. Here is a good example of what I often do with "scrap" wood - a cutting board.

I've made several of these over the years. The one pictured above if made with maple and walnut because that's what I had left over. You can choose many hardwoods as long as they're relatively hard (e.g. poplar would not be a great choice) and closed pored for sanitation (that rules out red oak and others). Walnut and maple make a great combination.

The finish on these pieces is about as easy as it gets. Just wipe on a liberal coat of mineral oil or two and it's good to go. As the surface wears from use you can occasionally re-apply the mineral oil to revitalize the surface.

Update 2004: Here are a few more I recently completed out of maple and walnut "scraps". Sizes of these boards range from about 8"x8" to 15"x19".

Update Oct 2005: After completing my new bench I had a bunch of 8/4 hard maple offcuts left over. There's no better wood than hard maple for cutting boards so I made up a couple thick ones. They both have routed juice slots and handles on the ends. Sizes are 11"x15" and 14"x23", both 1-3/4" thick.

Update Jul

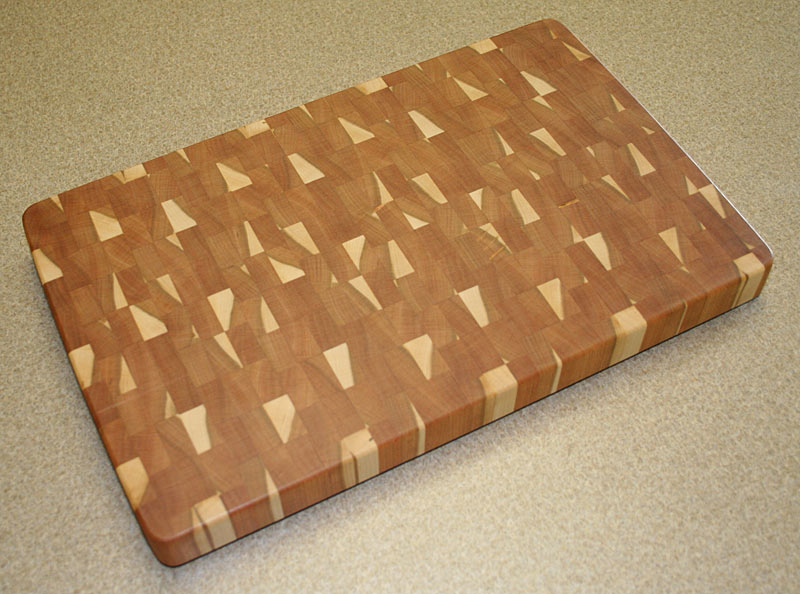

2009: this

is my first end grain board. Pretty neat - I'll be making more for sure.

This

is from a twisty board full of sapwood - the worst of the bunch from a

pile of log run cherry we purchased a few years back. I've been using

the other sappy boards for secondary wood (drawer boxes, dust panels,

etc) but I have a few boards that twisted too badly to be used for even

that kind of stuff. So as an experiment I cut this board up into short

sections (18"ish) and face-jointed and planed them flat. Even with

boards that short they ended up being under 1/2" thick. So I laminated

a pile of them into this end grain cutting board. Worked out pretty

well, and it's probably one of the best uses for these twisty boards.

The

board ended up a nice size: 12-1/4" x 7-3/4" x 1-1/16". Finish is a few

coats of a mineral oil and paraffin (or maybe beeswax - can't recall

which one I used) mixture heated to soak in. I routed two "handles" on

the bottom side so that it's easy to pick up and added 4 rubber feet to

keep it stable and ensure even air circulation around the end grain.

Update Nov

2014: Couple

more like the one above. From junky sappy cherry.

Makes a nice pattern for an end grain cutting board.

© Copyright 2014 Chris Billman